ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreThe PowerPouch™ IM packager offers versatile sealing options, including the highly popular 3-sided seal pouches. This sealing method secures the pouch on the top and two sides before cutting and discharging, ensuring product integrity and efficient processing. 3-sided seal pouches are ideal for powders and dry fills, making them a preferred choice for products such as drink mixes, cocoa, and dry soup mixes.

The PowerPouch™ IM packager provides multiple sealing options, including the 4-sided seal pouch – a preferred choice for products requiring enhanced durability and presentation. This method seals the pouch on all four sides (top, bottom, and sides) before cutting and discharging, creating a sleek, uniform appearance. Customers value the 4-sided seal pouch for its crisp, professional finish, making it ideal for powders, dry goods, and products that benefit from a secure, even bottom seal.

The PowerPouch™ IM packager offers flexible pouch forming options, including the addition of bottom gussets to maximize capacity without altering the pouch's height or width. Gusseted pouches can hold more product, providing increased volume while maintaining a compact footprint. This design enhances shelf appeal, as most gusseted pouches are capable of standing upright for improved product visibility and presentation.

The Stand-Up pouch has all of the benefits of a Gusseted pouch, but includes a button seal, sealing the bottom corners of the pouch together, which forms a rounded bottom providing better stand-up capability.

The PowerPouch™ IM packager can be equipped with a zipper closure, allowing pouches to be resealed after the initial top seal is opened. This added functionality enhances product freshness and convenience, making it a popular choice for gusseted pouches and 3-sided seal pouches. The zipper feature can be integrated into both new and existing machines, depending on the length of the bag-forming section.

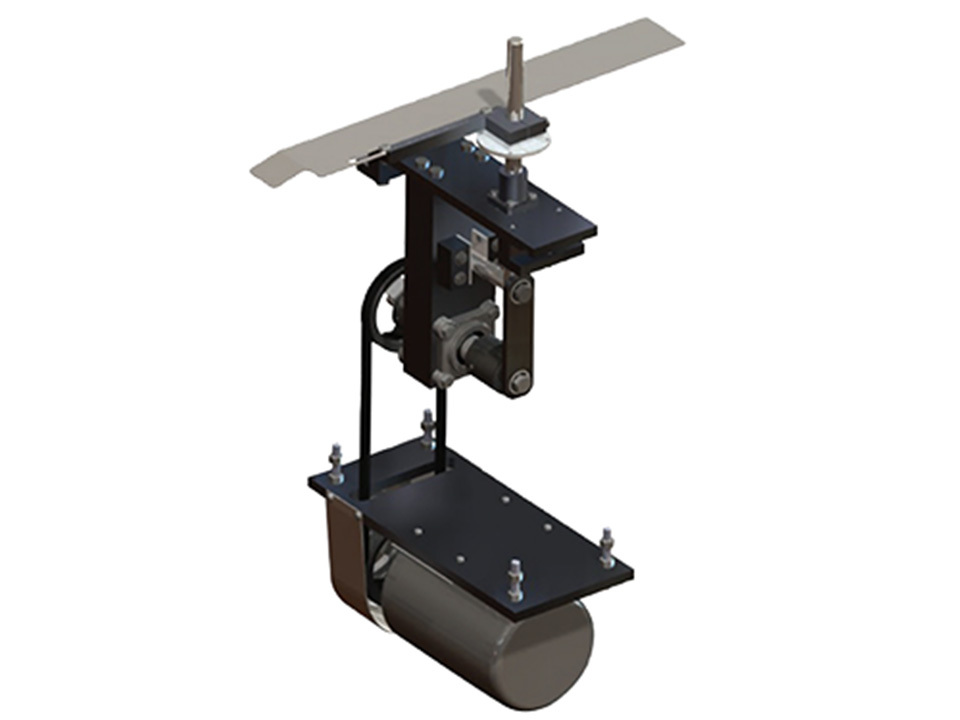

The Die-Cut Assembly can be incorporated into the pouch machine to create special pouch forms. This device can use either mechanical or pneumatic means to push a punch through sealed pouch film and into a receiving die. Typical uses include making pouches into bottle or other specialty shapes.

The Hole Punch Assembly can be incorporated to add a hole into the top of the pouch to allow for hanging on a store rack. Many hole sizes and shapes are available, including full round, 270°, Sombrero and Bottle-Neck.